| 厚さ (mm) | 0.015 – 0.5 |

| 幅 (mm) | 100 – 1600 |

| Length | Customer‑specified |

| Material States | ○, H14, H16, H18, H19, H22, H24 |

| Typical Alloys | 8011 Aluminum |

| Annual Production Capacity | ≥ 100 kt |

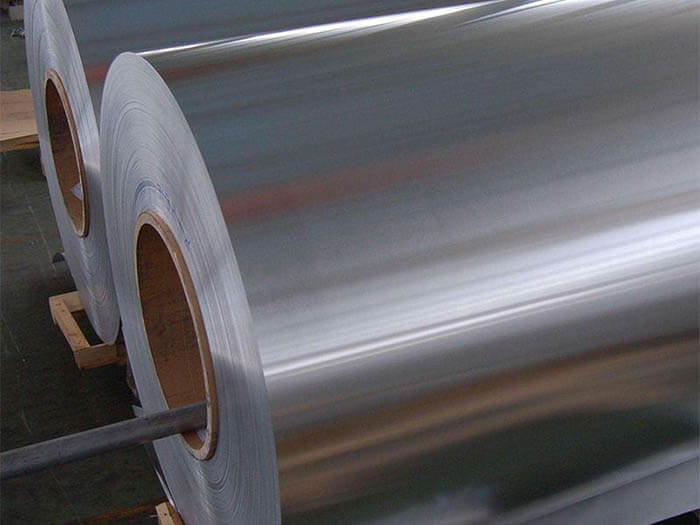

Langhe Materials proudly introduces our flagship product, 8011 アルミホイル, engineered to meet the highest standards in packaging, industrial, and specialty applications. With a processing width range of 100–1600 mm and thickness options between 0.015–0.5 mm, our 8011 foil combines versatile formability with exceptional barrier properties. Produced in states from O to H24, it offers superior mechanical strength, puncture resistance, and moisture and light blocking, making it ideal for pharmaceutical, food, beverage, and industrial uses. Backed by Langhe’s robust annual capacity exceeding 100 kt and customizable order volumes from 2 t to 5000 t, 8011 Aluminum Foil ensures reliable supply and tailored solutions for global clients.

Langhe’s 8011 Aluminum Foil is an 8-series aluminum alloy primarily alloyed with iron and silicon, with total alloying elements exceeding 1 % to enhance formability and strength . Available in material states O, H14, H16, H18, H19, H22, and H24, it caters to diverse requirements from deep drawing to cold form applications. Our foil undergoes A‑grade wet coating, ensuring a clean surface free from stains, mottles, or pinholes, and offering a smooth, uniform finish .

8011 Aluminum Foil’s performance derives from its alloying constituents:

| パラメータ | Value |

|---|---|

| 厚さ (mm) | 0.015 – 0.5 |

| 幅 (mm) | 100 – 1600 |

| Length | Customer‑specified |

| Material States | ○, H14, H16, H18, H19, H22, H24 |

| Typical Alloys | 8011 Aluminum |

| Annual Production Capacity | ≥ 100 kt |

Data sourced from our production records and industry benchmarks .

| Sector | 応用例 |

|---|---|

| Pharmaceutical | PTP blister foil, capsule blister packaging |

| 食べ物 & Beverage | Yogurt lids, meal trays, beer bottle seals |

| Beverage Closure | Wine and spirits bottle caps |

| Industrial | Cable shielding foil, transformer insulation |

| Consumer Goods | Tear‑off lids for infant formula, condensation caps |

Langhe’s 8011 foil excels in blister packaging due to its formability and A‑grade wet coating, delivering superior seal integrity and moisture protection .

Langhe Materials operates multiple continuous casting and rolling lines, yielding an annual output exceeding 100 kt of aluminum plate, coil, and foil products . We accommodate batch sizes from 2 t to 5000 t to fit customer schedules, with lead times ranging from 7 に 45 days based on order volume and thickness .

Our stringent quality controls—encompassing raw material selection, semi‑finished and finished product testing—ensure each batch meets or exceeds industry standards .

8011 foil is supplied in protective packaging to prevent oxidation and mechanical damage:

With global export capabilities, we ship via sea, rail, or road to major markets in Asia, Europe, the Americas, and beyond, ensuring safe and timely delivery in 7–45 days .

For inquiries, samples, or quotations:

Experience the Langhe difference in quality, reliability, and service with our premium 8011 アルミホイル. We look forward to partnering with you to enhance your products and processes.

当社のアルミ箔製品は幅広い業界や用途で使用されています, 梱包も含めて, 自動車, 工事, 電子機器と家庭用. 応用例をいくつか紹介します:

アルミ箔の用途

医薬品用アルミ箔

家庭用アルミ箔

保温用アルミ箔

アルミホイルダクト

蓋付きアルミ食品容器

チョコレート軟包装金アルミ箔

ハニカム用アルミホイル

ケーブルアルミ箔

アルミ箔テープ

空調フィン用親水性アルミ箔

アルミ箔をヒートシールする

水ギセルアルミホイル

髪のアルミホイル

ボトルキャップシール用アルミ箔

食品軟包装用アルミ箔

タバコホイル

電池用アルミ箔

アルミホイルジャンボロールの包装工程

港でのコンテナ積み込み